Products

| DESIGN FEATURES 設計要點 |

|

The butterfly valve can be classified to centric shaft, single eccentric, dual eccentric and tri-eccentric butterfly valves according to the relative positions of the valve seat and the valve shaft center or valve body center. 蝶型閥依閥座與閥軸中心或閥體中心的相對位置可分為中軸型蝶閥、單偏心蝶閥、雙偏心蝶閥、三偏心閥。 |

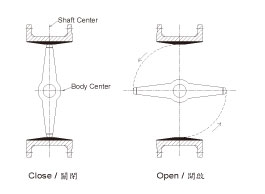

| Centric Shaft 直軸型設計 | |

|

The centric type butterfly valve is generally of full-lined rubber design, and its valve disc have double-sided pressure-holding characteristic. The shaft rubber of the valve body lining can isolate the valve shaft from the contact of fluid completely. It is the butterfly valve with high C/P value, simple structure and low price. 直軸型蝶閥通常為全內襯橡膠設計,且閥瓣具有雙面持壓特性,閥體內襯之軸部橡膠可以完全隔絕閥軸與流體接觸,是構造簡單便宜的高C/P值蝶閥。 |

|

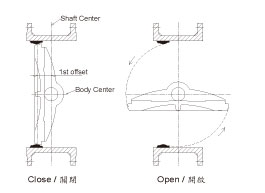

| Single Eccentric 單偏心設計 | |

| When the valve disc are open, the valve seat will be separated from the disc seat gradually. When they are fully open, only the valve seat near two sides of the valve shaft contacts the disc seat, but approaching separating status. This design is better than the straight shaft one, which reduces the extrusion and mechanical wear generated between the valve seat and disc seat during the operation process of the butterfly valve.

當閥瓣開啟時,閥座封會與閥座逐漸分離,當全開時唯有靠近閥軸兩側部分的座封會與閥座接觸但趨近於分離狀態,此設計型式比直軸型設計更為優良,能減少蝶閥在操作行程中座封與閥座之間所產生的擠壓和磨損。 |

|

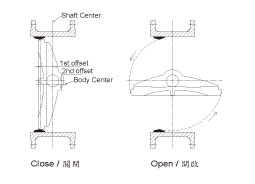

| Dual Eccentric 雙偏心設計 | |

|

The dual eccentric valve seat design achieves more ideal sealing and pressure-resistant performance when the valve disc are fully closed, and reduce the torque effectively and increase the valve seat’s service life. 雙偏心的閥座設計,使閥瓣位於全關位置時,擁有更理想的密封耐壓性能,並且能有效降低操作扭矩以及增加座封的使用壽命。 When the valve disc are open, the valve seat will be separated from the disc seat more quickly; when they are fully open, the valve seat will be completely separated from the disc seat, avoiding permanent deformation of the valve seat near two sides of the valve shaft, which will affect the valve’s sealing performance. 當閥瓣開啟時,閥座封與閥座能更快的分離,且當全開時座封與閥座能徹底分離,能避免靠近閥軸兩側部分的座封產生永久性變形,影響閥的密封性能。 |

|

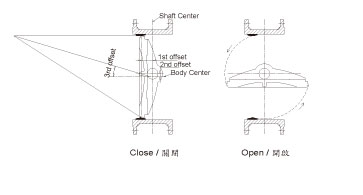

| Tri-Eccentric 三偏心設計 | |

|

The tri-eccentric valve seat design achieves perfect sealing and pressure-resistant performance when the valve disc are fully closed, and can reduce the operating torque significantly and increase the seat’s service life considerably. 三偏心的閥座設計,使閥瓣位於全關位置時,擁有完美的密封耐壓性能,並且能大大降低操作扭矩以及大大增加座封的使用壽命。 When the valve disc are open, the valve seat will be separated from the disc seat immediately. During the operating process, there is almost no friction stroke, which can eliminate the mechanical wear and scratch generated between the valve seat and disc seat. Therefore, it is commonly applied to the metal-metal valve seat design, and suitable in high-temperature and high-pressure fluid environment. 當閥瓣開啟時,座封與閥座能立刻的分離,操作過程中幾乎無任何的摩擦行程,能徹底消除座封與閥座間所產生的機械磨損和擦傷,因此通常應用於金屬-金屬的閥座設計,適用於高溫、高壓的流體環境。 |

|

Please download Our Catalog to discover the parts you are looking for or Contact us.

更多詳細內容,請下載型錄或聯絡我們。